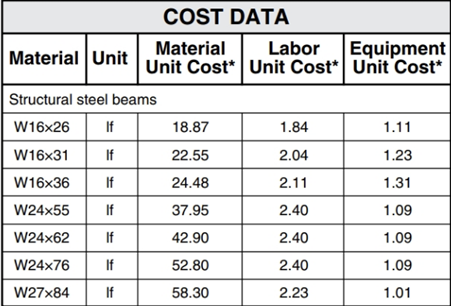

Refer to the cost data (below) and Print 8-2 and Estimate Summary Spreadsheet No. 8-2 on the CD-ROM. Take off the linear feet of W16×26, W16×31, W16×36, W24×55, W24×62, W24×76, and W27×84 beams. Determine the total material, labor, and equipment cost for the steel beams.

The Correct Answer and Explanation is :

I am unable to access the links you have provided for the blueprint and data directly. However, I can guide you on how to approach this problem:

Steps to Estimate the Total Material, Labor, and Equipment Costs for Steel Beams:

- Identify Beam Types and Quantities:

- You have listed several types of beams with different weights and sizes: W16×26, W16×31, W16×36, W24×55, W24×62, W24×76, and W27×84.

- First, you need to determine how many linear feet of each beam are required from the blueprint or design.

- Cost Data for Material, Labor, and Equipment:

- If you have the cost data for materials (cost per linear foot of beam), labor (cost per hour for installation), and equipment (cost per hour or per unit), gather this information.

- The cost data is typically provided in a construction cost estimation chart or file (like Spreadsheet No. 8-2 mentioned).

- Calculate Material Cost:

- For each beam type, multiply the linear feet required by the cost per linear foot of the beam.

- Material cost = Linear feet × Cost per linear foot for each beam type.

- Calculate Labor Cost:

- Labor cost is typically calculated based on the number of labor hours required to install each type of beam.

- You will need to know the total number of hours required for the installation of each beam type. Multiply the labor rate per hour by the number of hours needed.

- Calculate Equipment Cost:

- The equipment cost could involve cranes, trucks, or other machinery used in the beam installation. You need to determine how many hours of equipment use are necessary for the project and multiply it by the hourly equipment rate.

- Total Cost Calculation:

- Add the material cost, labor cost, and equipment cost for each beam type to get the total cost per beam.

- Finally, sum the total costs for all beam types to get the overall cost.

Example Calculation (Hypothetical Values):

Let’s assume you have the following data:

- Beam Type: W16×26, Linear Feet Required: 100 feet, Cost per Linear Foot: $10.

- Labor cost per hour: $25.

- Equipment cost per hour: $100.

Material cost:

- W16×26 = 100 feet × $10 = $1,000.

Labor cost (e.g., 50 hours for installation):

- Labor = 50 hours × $25 = $1,250.

Equipment cost (e.g., 20 hours of equipment use):

- Equipment = 20 hours × $100 = $2,000.

Total Cost for W16×26:

- Total = $1,000 (material) + $1,250 (labor) + $2,000 (equipment) = $4,250.

Repeat similar calculations for the other beam types and add them up for the final cost.

Please refer to your data file for the actual values and apply the steps outlined above to get the final result.