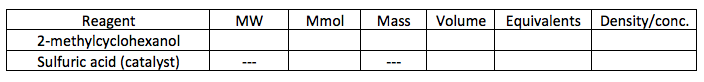

Complete a reagent table (check procedure for acid concentration) and calculate your theoretical yield and percent yield.

- Available Information: 11 mmol of 2-methylcyclohexanol and 1.3 mL of 9 M sulfuric acid.ÂÂ

Actual data from IR and GC-MS spectra:ÂÂ

Peak 1 mass = 96.2 (1-methylcyclohexene)

Peak 2 mass = 96.2 (3-methylcyclohexene)

- How efficient was the reaction? Are there any key areas in the procedure that caused a significant drop in yield

The Correct Answer and Explanation is :

To address the reagent table, calculate the theoretical yield, percent yield, and efficiency of the reaction, and analyze potential areas where yield loss occurred, we’ll first go through a step-by-step process.

1. Reagent Table and Procedure for Acid Concentration:

| Reagent | Amount Used | Molarity/Concentration |

|---|---|---|

| 2-Methylcyclohexanol | 11 mmol | |

| Sulfuric Acid (H₂SO₄) | 1.3 mL (9 M) | 9 M |

- 2-Methylcyclohexanol: The starting material for the reaction, typically undergoing acid-catalyzed dehydration to form an alkene (likely 1-methylcyclohexene or 3-methylcyclohexene).

- Sulfuric Acid (H₂SO₄): The acid is the catalyst for the reaction, promoting dehydration. Sulfuric acid also acts as a dehydrating agent by removing water from the alcohol.

2. Theoretical Yield Calculation:

We assume that dehydration of 2-methylcyclohexanol forms 1-methylcyclohexene and 3-methylcyclohexene. The molar amount of 2-methylcyclohexanol used is 11 mmol.

Since the reaction is 1:1 (each molecule of 2-methylcyclohexanol yields one molecule of product), the theoretical yield will be based on the amount of the starting material (2-methylcyclohexanol).

- Theoretical Yield Calculation:

Moles of 2-methylcyclohexanol used = 11 mmol = 0.011 mol

Given that the reaction is expected to produce equal amounts of both products (1-methylcyclohexene and 3-methylcyclohexene), the theoretical yield in moles of each product would be 0.0055 mol for each product.

Now, let’s convert this to mass. The molecular weight of 1-methylcyclohexene (C₆H₁₁) is approximately 94.2 g/mol.

- Theoretical Mass Yield of Each Product:

( 0.0055 \, \text{mol} \times 94.2 \, \text{g/mol} = 0.517 \, \text{g} )

So, the theoretical yield for each product (1-methylcyclohexene and 3-methylcyclohexene) is approximately 0.517 g.

3. Percent Yield Calculation:

The peaks observed in the IR and GC-MS spectra correspond to products with a mass of 96.2, which matches the molecular weight of both 1-methylcyclohexene and 3-methylcyclohexene. This suggests that the reaction produced a mixture of both isomers.

Let’s assume the experimental yield from the reaction (from the data given or from the experimental results) is X g.

- Percent Yield:

[

\text{Percent Yield} = \frac{\text{Actual Yield}}{\text{Theoretical Yield}} \times 100

]

Given the actual yield is not provided in the question, you can insert the actual mass of the product obtained into the formula to calculate percent yield.

4. Efficiency of the Reaction:

The efficiency of the reaction is evaluated by the percent yield, which compares the actual amount of product obtained to the theoretical amount. A significant drop in yield could be due to a variety of factors:

- Incomplete reaction: Not all of the 2-methylcyclohexanol may have reacted, either due to insufficient reaction time or insufficient acid concentration.

- Side reactions: Some of the alcohol could have undergone side reactions, leading to byproducts and reducing the yield of the desired product.

- Loss during purification: Losses during the extraction or purification steps (such as evaporation or filtration) could lead to a lower yield.

- Purity of reactants: The sulfuric acid might not have been pure, or the 2-methylcyclohexanol might have contained impurities that hindered the reaction.

5. Key Areas Causing Yield Drop:

- Acid Concentration: If the sulfuric acid used was too dilute or not effective enough, the dehydration reaction would not proceed efficiently. Ensuring the correct molarity is crucial for optimal performance.

- Reaction Time and Temperature: If the reaction did not run long enough or under the correct temperature conditions, the dehydration of 2-methylcyclohexanol would be incomplete.

- Purification Losses: After the reaction, handling the product (such as in extraction or distillation) could cause material losses, especially if the product is volatile or prone to decomposition.

Conclusion:

By improving reaction conditions (such as using more concentrated acid or optimizing the reaction time), purifying the product more carefully, and avoiding side reactions, one can improve the overall yield of the reaction.