What Does X.X, X.XX, And X.XXX Signify In An Engineering Drawing Title Block? (Explain With A Representative Dimensioned

The correct answer and explanation is :

In an engineering drawing, dimensions are provided in the title block to describe the exact measurements and scale of the drawing. These dimensions, typically listed in various formats, such as X.X, X.XX, and X.XXX, indicate the level of precision and accuracy in the measurements.

- X.X (One Decimal Place):

- This format signifies that the measurement is given to one decimal place. It is typically used when a lower degree of precision is sufficient, such as when the exact measurement is not critical to the design or function of the part.

- Example: If a dimension is 5.3, it means the length of the object is measured to the nearest tenth of a unit (such as millimeters or inches).

- X.XX (Two Decimal Places):

- This format signifies that the measurement is provided with two decimal places. It offers a higher degree of precision compared to X.X and is often used when more accuracy is necessary for the part’s function or fitting with other components.

- Example: A dimension of 15.75 would indicate a length measured to two decimal places, meaning the measurement is accurate to the hundredth.

- X.XXX (Three Decimal Places):

- This format provides the highest level of precision, with three decimal places. It is used in cases where minute details or very high accuracy are required, such as in components where tight tolerances are critical, like aerospace or precision machinery parts.

- Example: A dimension of 25.375 means the measurement is accurate to the thousandth of a unit.

Explanation:

The choice of how many decimal places to use depends on the design requirements and the tolerance level needed for the part. For instance, in high-precision engineering, such as the aerospace or medical industries, components may need to be measured with extreme accuracy (X.XXX), whereas for simpler designs with less stringent requirements, measurements may be rounded to one or two decimal places (X.X, X.XX). These conventions help maintain consistency and provide clarity regarding the level of detail needed for fabrication.

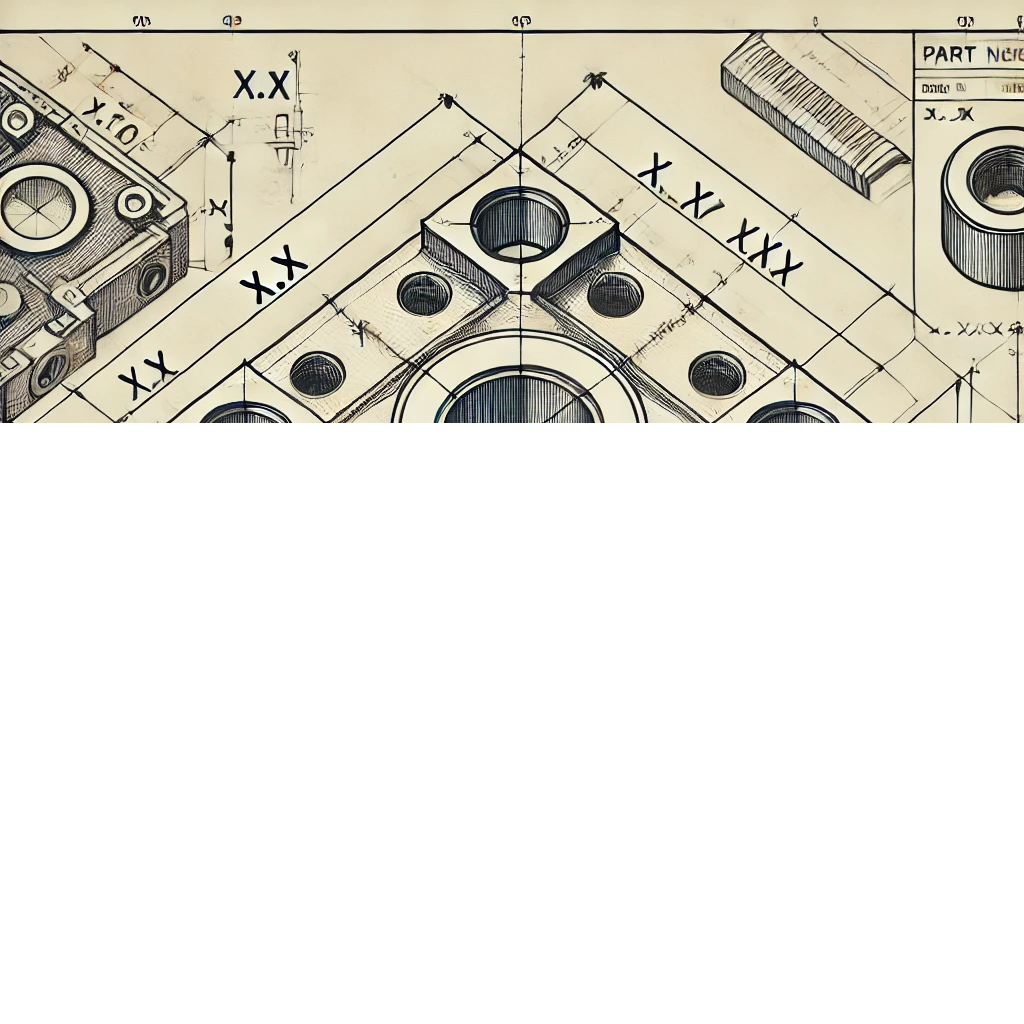

Here is a representative engineering drawing that illustrates the use of X.X, X.XX, and X.XXX in dimensioning. You can see that different levels of precision are applied depending on the requirement of the part.

- X.X (One Decimal Place): The first dimension shows a measurement rounded to one decimal place.

- X.XX (Two Decimal Places): The second dimension has two decimal places, offering more precision.

- X.XXX (Three Decimal Places): The third dimension is provided with three decimal places, indicating high precision.

These varying levels of precision are essential in engineering to ensure parts fit together correctly and meet design specifications, depending on their function and the tolerances required for the specific application.