Which of the following is true about MRP?

MRP is the highest level of planning in most organizations.

MRP is used to determine the number of parts, components, and other materials needed to produce a product.

MRP is not used for dependent demand items.

MRP is an acronym for Material Requirements Planning.

The correct answer and explanation is :

The correct answer is:

MRP is used to determine the number of parts, components, and other materials needed to produce a product.

Explanation:

Material Requirements Planning (MRP) is a crucial production planning and inventory control system used in manufacturing to ensure that materials and components are available for production at the correct time and in the right quantity. MRP helps in determining the materials required to produce finished products and when to procure them. It involves the calculation of the required quantities for raw materials, parts, and components based on the production schedule, bill of materials (BOM), and inventory status.

Let’s analyze the given options:

- MRP is the highest level of planning in most organizations:

- This is incorrect. MRP is not the highest level of planning. The highest level of planning in most organizations is typically the Aggregate Planning or Sales and Operations Planning (S&OP), which focuses on balancing supply and demand. MRP works at a more detailed level, typically at the level of components and materials.

- MRP is used to determine the number of parts, components, and other materials needed to produce a product:

- This is true. MRP calculates the required quantities of parts and materials needed to meet production schedules and customer demands. It is based on information from the bill of materials (BOM), inventory levels, and production orders.

- MRP is not used for dependent demand items:

- This is false. MRP is specifically used for dependent demand items. Dependent demand refers to items whose demand is directly related to the production of another item, like components or subassemblies that are needed to manufacture a finished product.

- MRP is an acronym for Material Requirements Planning:

- This is also true, but it’s not the main focus of the question, as the correct answer pertains to what MRP actually does.

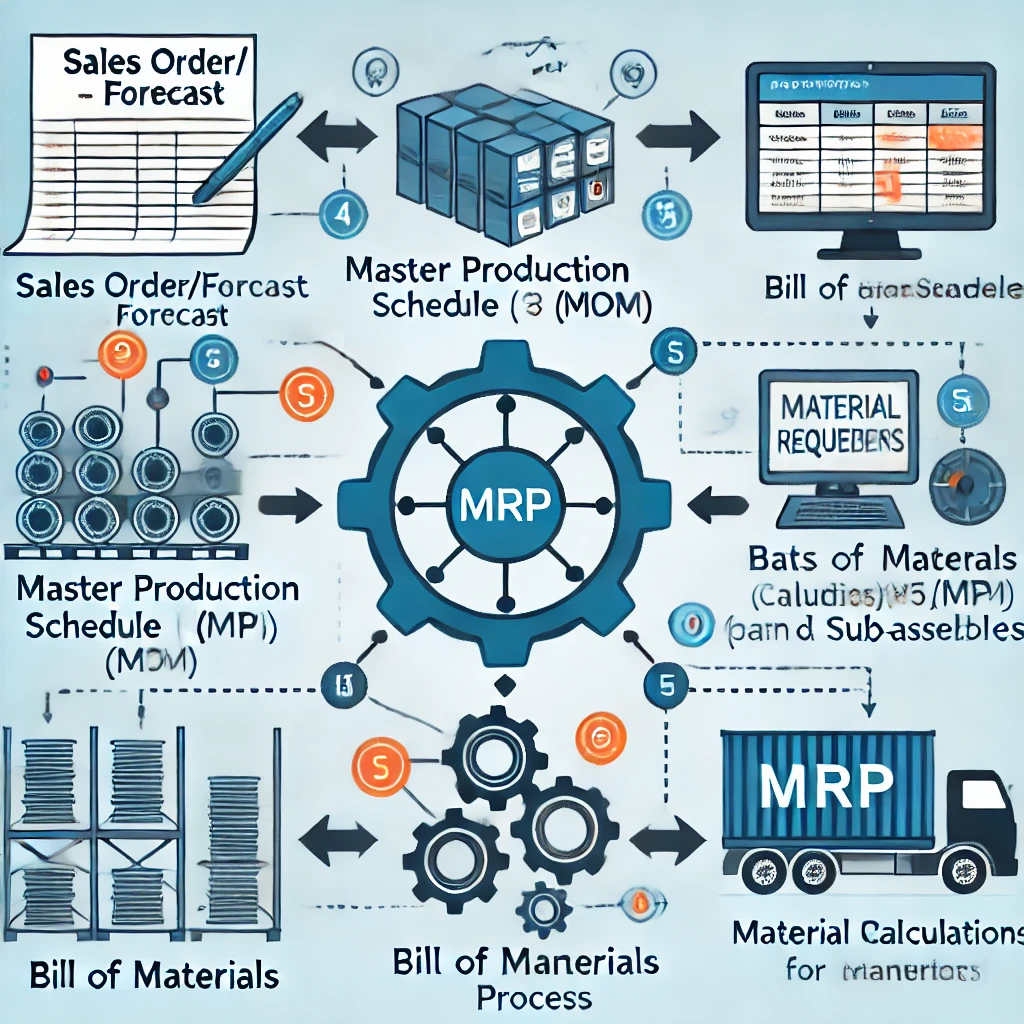

Image:

The image above illustrates the concept of Material Requirements Planning (MRP) in a manufacturing environment. It shows the flow of information from sales orders and forecasts to the final MRP calculations, determining the material requirements for parts, components, and subassemblies. This process is essential for ensuring that all necessary materials are available for production in the right quantity and at the right time.