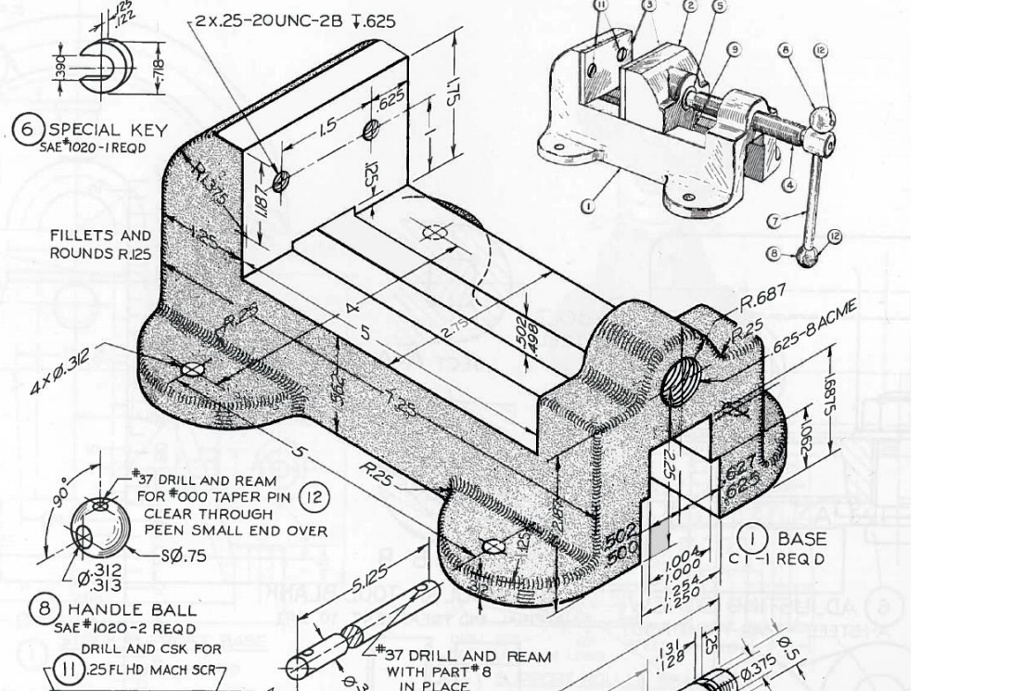

25 122 718 2x.25-20UNC-2B 1.625 6 SPECIAL KEY SAE 1020-I REQD FILLETS AND ROUNDS R.125 R1375 125 4×0.312 1.187- 1.5 625 562 5 125- 725 06- 313 5 #37 DRILL AND REAM FOR #000 TAPER PIN (12 CLEAR THROUGH PEEN SMALL END OVER -SØ.75 8 HANDLE BALL SAE#1020-2 REQD DRILL AND CSK FOR 1.25 FL HD MACH SCR7 1 SCR7 R.25 -5.125- ? 2.7 1.75 502 498 -R.687 R25 625-8 ACME -1.6875- #37 DRILL AND REAM WITH PART#8 IN PLACE 502 2.25 1.004 1.000 1.254 1250 12 627 625 1.062- 1) BASE CT-I REQ D 0.375 0.5

The Correct Answer and Explanation is:

This is a technical drawing of a bench vise.

The image presents a detailed engineering blueprint used for the manufacture and assembly of a mechanical bench vise. It includes several distinct views to convey all necessary information. The most prominent part of the drawing is a large, dimensioned isometric view of the vise’s main component, labeled as part number 1, the “BASE”. This view provides precise measurements for all its features, such as its overall length, height, and width, the location and size of the four mounting holes (4xØ.312), and the specifications for the slideway where the movable jaw will slide.

In the upper right corner, an assembled isometric view shows the complete vise, illustrating how all the individual components fit together. This assembly view uses callout numbers to identify key parts, including the base (1), the movable jaw (2), jaw faces (3 and 4), the main screw (5), and the handle assembly (6, 7, 8). This view provides context for the individual part drawings.

The drawing also includes detail views for smaller, specific components. For example, there is a detailed drawing for part 6, a “SPECIAL KEY”, and for part 8, a “HANDLE BALL”. These focused drawings provide the exact dimensions and manufacturing notes required for these smaller pieces. The notes on the drawing provide crucial manufacturing specifications, such as the material for the base being cast iron (“CI-1 REQ’D”), the type of thread for the main screw hole (“.625-8 ACME”), which is a strong thread form suitable for high loads, and general tolerances like “FILLETS AND ROUNDS R.125”. Overall, this is a comprehensive document that guides the entire production process of the bench vise.